The History of Solenoid Valves

Early Invention and Industrial Adoption

The first solenoid valves were introduced in 1910 by the Automatic Switch Company (ASCO). Originally developed to complement electrical switches, solenoid valves quickly became valuable in applications requiring automatic control of fluid and gas. Their ability to integrate with level switches, float switches, and temperature switches made them indispensable across industries.

Constructed from materials such as bronze, stainless steel, aluminum, and plastic, solenoid valves proved both versatile and resilient. Over the decades, their reliability has made them nearly recession-proof, with adoption across industries as diverse as water treatment, energy, and entertainment.

Expanding Industrial Applications

By the mid-20th century, solenoid valves were being used in a wide range of sectors:

- Service Industry: Car and truck washes (soap and rinse valves)

- Mining: Safety spray-down equipment in strip mines

- Automotive: Cooling jackets for seat foam in assembly lines

- Medical: Autoclaves and sterilization systems in hospitals

- Entertainment: Special effects such as simulated lava flows for themed attractions

As industries grew, so did demand for valves capable of meeting specialized requirements. Manufacturers responded by innovating features that improved performance, reliability, and safety.

Key Innovations in Solenoid Valve Design

Several manufacturers contributed notable advancements in solenoid valve technology:

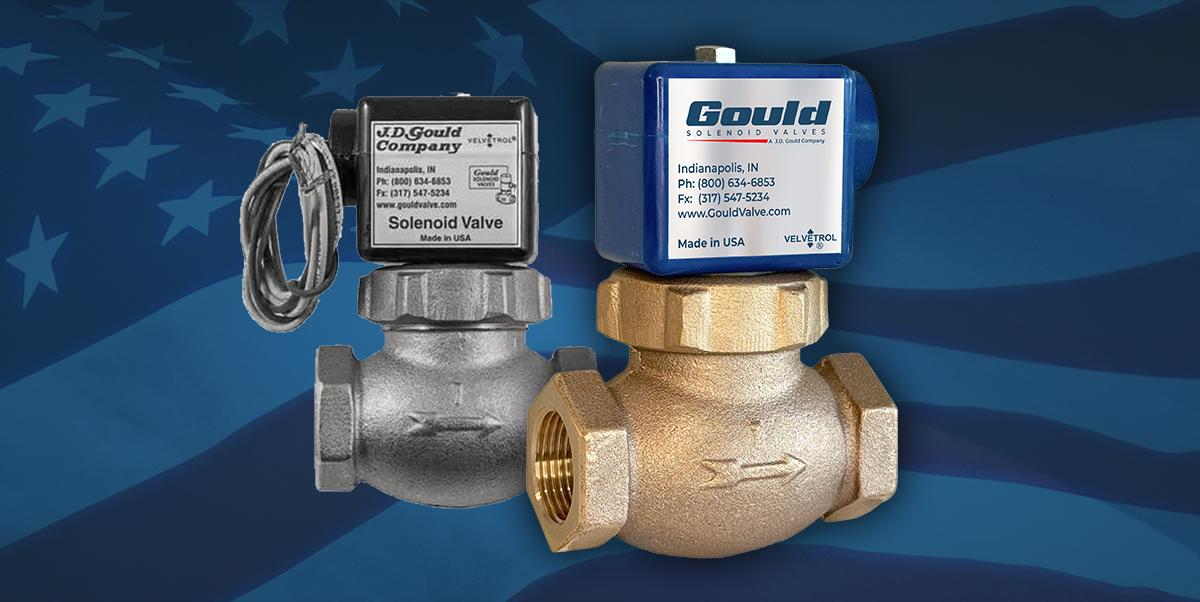

- Gould Velvetrol®: A cushion-close feature designed to reduce water hammer.

- Bürkert (1950s): Pioneered the development of plastic-bodied solenoid valves.

- Industry-wide advancements: Enhancements to diaphragm-type solenoid valves, as well as the introduction of manual reset, air-operated, and normally open designs.

By the 1990s, solenoid valves were standardized globally, with governments, industries, and independent organizations aligning on quality and performance expectations.

Modern Developments and Energy Efficiency

Today’s solenoid valves continue to evolve with a focus on sustainability and efficiency. New coil designs drastically reduce energy consumption. The double direct-acting coil, for example, uses one winding to open the valve and a lower-power winding to hold it open, reducing energy use by up to 75%.

Even conventional single coil valves have been optimized. Advanced electronics allow for an initial surge of current to actuate the valve, followed by a reduction of up to 95% to maintain the open state. These improvements not only lower operating costs but also extend coil life.

A Century of Progress

From their beginnings in 1910 to modern energy-saving innovations, solenoid valves have become integral to countless industries and systems. Their evolution reflects the broader trajectory of industrial automation: improving efficiency, safety, and reliability.

Gould continues to play a role in this history by delivering American-made solenoid valves built for durability and dependable performance in demanding environments.